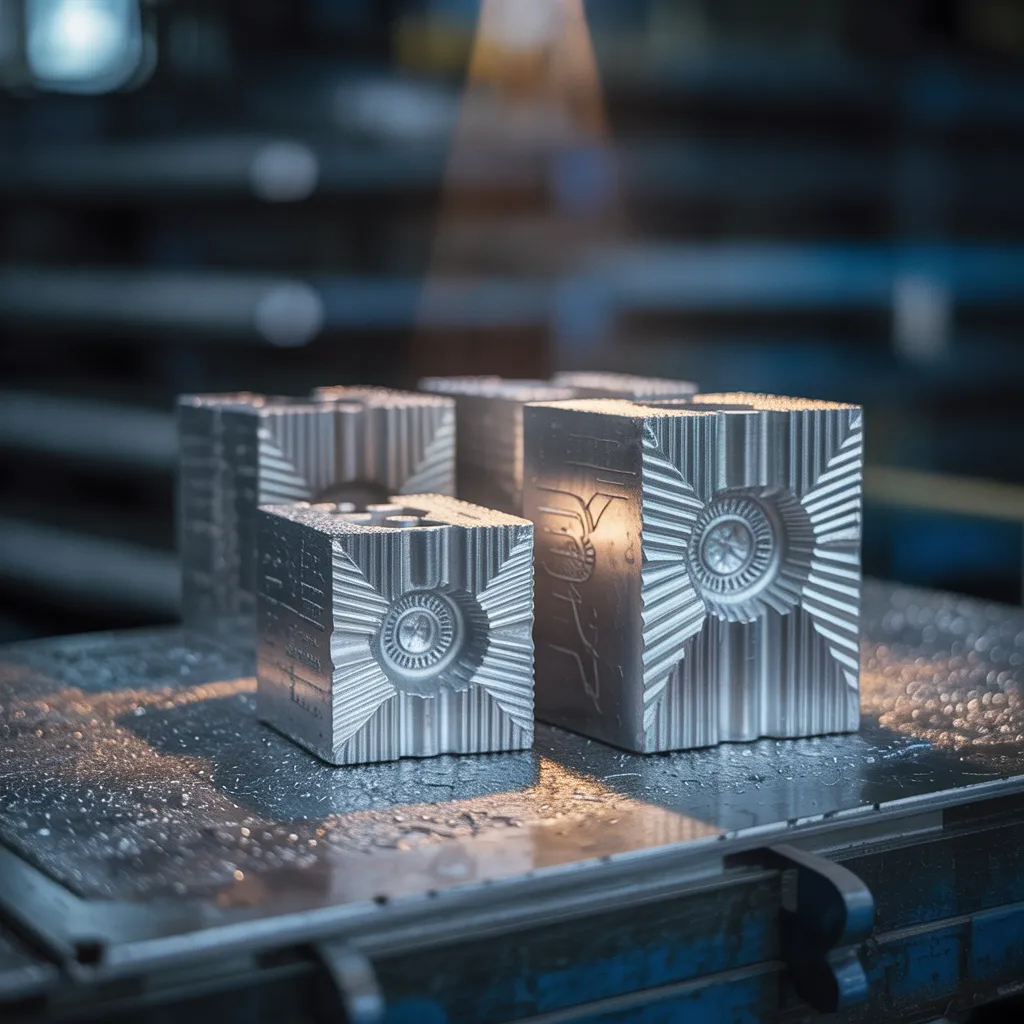

American-Made Alloy Castings for Industrial Applications

Innovations in Aluminum Casting Techniques for Modern Industries

Advancements in aluminum casting technologies are reshaping multiple industries by enhancing efficiency and precision. Techniques such as 3D printing and automation are enabling the creation of intricate designs while reducing waste. Moreover, the introduction of eco-friendly alloys supports sustainability goals. As these innovations progress, they raise questions about their long-term impact and potential applications across sectors. What might the future hold for aluminum casting in an increasingly eco-conscious world?

Aluminum Casting Introduction: Fundamentals and Advancements

Aluminum casting is a vital process in industrial fabrication, defined by its potential to create complex shapes with exactitude. This flexible technique entails pouring molten aluminum into a mold, permitting it to solidify into the intended form. Various methods, including sand casting, die casting, and investment casting, each present unique advantages that serve different applications. Sand casting is chosen for its cost-effectiveness and flexibility, while die casting is known for its productivity in producing mass-production parts with tight tolerances. Breakthroughs in aluminum casting have concentrated on enhancing material properties, optimizing energy efficiency, and reducing waste. Cutting-edge technologies such as computer-aided design (CAD) and simulation software have streamlined the design process, enabling manufacturers to refine molds and predict casting outcomes. These improvements not only improve product quality but also allow faster production cycles, establishing aluminum casting as a essential component in modern industrial applications, from automotive to aerospace.

The Advancement of 3D Printing in Aluminum Casting

As the demand for more innovative manufacturing solutions grows, 3D printing has appeared as a transformative force in aluminum casting. This technology enables manufacturers to fabricate complex geometries that were previously difficult or impossible to achieve with traditional methods. By leveraging additive manufacturing techniques, companies can decrease material waste and shorten production cycles, making the casting process more efficient and cost-effective.

Additionally, 3D printing enables rapid prototyping, permitting more rapid iterations and refinements in design. This agility is essential in industries such as aerospace and automotive, where exact specifications are essential. Additionally, the integration of 3D printing in aluminum casting can result in enhanced customization, enabling manufacturers to meet specific client needs with greater ease. As this technology continues to develop, it is ready to redefine the landscape of aluminum casting, fostering innovation and enhancing overall manufacturing capabilities across diverse sectors.

Improved Alloys: Breakthroughs in Aluminum Casting Compounds

The development of sophisticated alloy formulations has considerably transformed aluminum casting materials. Innovations in high-strength and lightweight alloys are empowering manufacturers to produce components that achieve rigorous performance standards while reducing overall weight. These improvements are vital for industries striving to increase efficiency and sustainability in their products.

Advanced Specialty Alloy Blends

Though innovations in aluminum casting materials keep evolving, advanced alloy formulations stand out as a significant development in the industry. These formulations are developed to boost specific properties such as corrosion resistance, thermal conductivity, and mechanical strength. By adding elements like silicon, magnesium, and copper, manufacturers can adapt alloys to fulfill the demanding requirements of various applications, from aerospace to automotive. The implementation of computational modeling and simulation techniques has accelerated the discovery and optimization of these advanced alloys, facilitating more efficient production processes. Moreover, the adoption of these innovative formulations contributes to minimizing waste and energy consumption during casting. As industries seek to improve performance and sustainability, advanced alloy formulations represent a critical advancement in aluminum casting technology.

Lightweight yet High-Strength Alloys

Developments in aluminum casting have facilitated the development of lightweight and high-strength alloys, which are increasingly important in meeting industry demands for enhanced performance without compromising structural integrity. These alloys, such as the Al-Li and Al-Zn systems, present superior strength-to-weight ratios, making them ideal for aerospace, automotive, and industrial applications. Breakthroughs in casting techniques, including die casting and semi-solid processes, have further enabled the production of these advanced materials with improved mechanical properties. Additionally, the incorporation of alloying elements such as magnesium and silicon increases corrosion resistance and weldability. As industries prioritize sustainability, lightweight alloys also promote energy efficiency by reducing fuel consumption in transportation applications, demonstrating their crucial role in modern engineering solutions.

How Automation Is Boosting Casting Efficiency

Automated technology transforms aluminum casting by optimizing workflows and increasing precision levels. The integration of robotic mechanisms and state-of-the-art applications provides real-time monitoring and control of casting processes, significantly minimizing the chance of human error. These systems can efficiently manage the temperature and composition of molten aluminum, ensuring consistency in product quality.

Furthermore, automation enables faster turnaround times by streamlining workflow and minimizing manual labor. Automated equipment can run without interruption, increasing production rates while upholding high standards. Additionally, data analytics tools provide insights into operational effectiveness, allowing manufacturers to make data-driven adjustments that enhance overall performance.

As a result, organizations can achieve greater yields and minimized waste, in the end translating to cost savings. With these advancements, automation not only increases efficiency in aluminum casting but also paves the way for future innovations in manufacturing practices. This shift constitutes a essential development in meeting the demands of modern industries.

Eco-Friendly Advancements in Metal Casting with Aluminum

Eco-friendly advancements in aluminum casting are increasingly focused on reprocessing aluminum components and utilizing energy-efficient casting techniques. Furthermore, the development of environmentally conscious alloys is gaining traction, aimed at reducing the environmental impact of the casting process. These advancements not only promote sustainability but also enhance the overall efficiency of aluminum production.

Repurposing Aluminum Resources

Though the aluminum casting industry has long relied on virgin materials, the growing emphasis on recycling aluminum is reshaping its landscape. Industry stakeholders increasingly recognize the environmental and economic benefits of employing recycled aluminum, which requires only 5% of the energy needed for primary production. This shift not only lowers greenhouse gas emissions but also cuts down on waste, fostering a circular economy. Cutting-edge technologies, such as sorting and refining processes, elevate the quality of recycled aluminum, making it a practical alternative for diverse applications. In addition, the integration of recycled materials into casting processes promotes innovation, permitting manufacturers to reach sustainability goals while maintaining performance standards. As a result, recycling is becoming a cornerstone of modern aluminum casting practices.

Energy-Efficient Casting Methods

The aluminum casting industry is increasingly adopting energy-efficient approaches as it seeks to boost sustainability together with the use of recycled materials. Methods such as low-pressure casting and die casting have gained prominence due to their ability to reduce energy consumption while maintaining high-quality outputs. Furthermore, advancements in furnace technologies, including induction heating, have significantly reduced energy use during the melting process. The integration of automation and process optimization further streamlines production, resulting in reduced energy requirements. Additionally, the industry is exploring renewable energy sources, such as solar and wind power, to minimize reliance on fossil fuels. By utilizing these energy-efficient casting techniques, the aluminum casting industry is making strides toward a more sustainable future while satisfying the demands of modern industries.

Eco-Friendly Metal Alloy Advancement

Pioneers in the aluminum casting industry are actively developing eco-friendly alloys that focus on both performance and environmental stewardship. These innovations focus on minimizing the carbon footprint connected to traditional aluminum production by incorporating recycled materials and alternative, less harmful elements. Researchers are investigating innovative combinations of aluminum with materials such as magnesium and silicon, working to enhance mechanical properties while minimizing ecological impact. Additionally, the development of bio-based additives is gaining traction, further reducing reliance on petroleum-based substances. Such efforts not only correspond with global sustainability goals but also address consumer demand for greener products. As these eco-friendly alloys gain momentum, they promise to revolutionize the industry, promoting a balance between high-quality performance and environmental responsibility.

Industry Applications of Contemporary Aluminum Casting in Numerous Industries

Today's aluminum casting technologies have reshaped numerous industries by delivering lightweight, sturdy, and economical solutions. In the automotive domain, these developments allow manufacturers to fabricate intricate engine components that boost fuel efficiency and minimize emissions. Likewise, the aerospace industry takes advantage of aluminum castings, which lead to weight reduction without diminishing strength, consequently boosting overall aircraft performance.

The consumer electronics field also uses modern aluminum casting processes to create sleek and durable housings for devices, guaranteeing durability while maintaining aesthetic appeal. Moreover, the construction industry employs aluminum castings for architectural features, offering both functionality and design flexibility.

Moreover, the clean energy industry utilizes these technologies for components in turbine systems and photovoltaic arrays, improving efficiency and sustainability. All in all, the varied applications of modern aluminum casting highlight its integral role in promoting technological advancement and productivity across multiple read the facts industries.

Questions & Answers

What Financial Considerations Come with New Aluminum Casting Technologies?

The financial implications of innovative aluminum casting technologies include substantial upfront investments in tools and staff education, prospective cuts in waste and labor costs, and long-term savings through enhanced productivity and production standards, favorably affecting overall profitability.

How Do Modern Technologies Impact the Recycling Process of Aluminum?

Innovations enhance the recycling process of aluminum by improving efficiency and minimizing energy consumption. Sophisticated processes streamline separation and melting operations, generating higher quality recycled material, eventually contributing to a more sustainable aluminum lifecycle and diminished environmental impact.

What Safety Measures Should Be Considered in Modern Aluminum Casting?

Safety considerations in modern aluminum casting include adequate ventilation to minimize fume inhalation, the use of PPE to avoid burns and injuries, and stringent adherence to industry regulations to maintain worker safety.

How Do Different Industries Prioritize Aluminum Casting Innovations?

Different industries prioritize aluminum casting innovations depending on distinct needs, such as weight reduction in automotive, corrosion resistance in aerospace, and cost efficiency in consumer goods, ensuring advancements align with operational goals and market demands.

What Certifications Are Available for Aluminum Casting Methods?

Multiple certifications are available for aluminum casting technologies, such as ISO 9001 for quality management, ISO/TS 16949 for automotive standards, and ASTM standards for material specifications, maintaining adherence to industry requirements and improving product reliability and safety.